Originally published November 22, 2024; updated October 27, 2025.

Every so often, there is a kerfuffle in the publishing world about the quality of print-on-demand (POD) books. In the latest flurry of opinions, bookstore manager Drew Broussard complained in an article on LitHub about the seemingly large influx of POD books with “low quality covers and paper, often poorly printed, and listed at a higher price than their regular-print brethren.” He goes on to depict POD as “fast fashion” and worries that “the sudden rise in ‘cheaper’ paperbacks might have a long-term negative effect on the publishing industry.”

Publishing consultant Jane Friedman (someone I follow regularly and a resource I often recommend) responded with a bit of historical context and pointed out some of the flaws in Broussard’s position. Others have weighed in as well (here’s one article).

I’m not going to rehash all the arguments. Instead, I thought I would take this opportunity to provide some observations about POD quality based on my decade of experience using it. I will focus on the two major POD platforms, Kindle Direct Publishing (KDP) and IngramSpark (IS), but I would anticipate many of the same observations apply to any other POD platform. I am setting aside writing and editing quality to focus on the production of books. And because we work primarily on nonfiction at Clear Sight Books, I’m setting aside color interiors (like those in children’s books).

What is print-on-demand (POD)?

Print-on-demand (POD) publishing uses digital printing to create one book at a time—kind of like printing a document on your laser printer, but fancier. It is often compared to “traditional” publishing, which usually entails a print run of hundreds or thousands of books.

Traditional publishing often uses offset printing, a printing method that involves transferring ink from a metal plate to a rubber blanket, then onto the paper. Offset printing offers more consistent quality than POD, but it takes significant setup, so you need a large enough print run to justify it. Because POD makes one book at a time, the unit cost is higher, but there is no need for the upfront outlay and complex setup.

Traditional publishing and POD may also use different binding methods, especially on hardbacks, which we’ll look at in a moment.

Who uses POD and why?

Traditional offset printing is commonly used by publishers doing large print runs, due to its consistent results and lower unit costs. In addition to being able to make the upfront investment, they also have the capacity to manage inventory and distribution.

Digital print-on-demand is used by some small presses and by most self-published authors. Because POD books are printed only when ordered, there is no need to hold and manage inventory. Additionally, POD allows for quick updates and personalization.

Independent authors usually use KDP and IngramSpark for POD. Small presses typically use Lightning Source, which is a sibling company of IngramSpark aimed at small presses; small presses are less likely to use KDP, especially if they are trying to reach brick-and-mortar bookstores (who are not big fans of Amazon, the owner of KDP).

In recent years, larger traditional publishers have begun to use POD. They have realized that they can improve their bottom line in two ways… First, certain events can cause a spike in demand for a book—for example, when a book wins an award. If you can’t meet the demand when people want the book, they will lose interest, and when that print run finally shows up in six months, you’ll end up with stacks of books on the remainder table.

Second, imagine the number of books a publisher might have in their catalog after years of being in business. But sales are typically strongest at release and then taper off. If each older title sells only a few dozen copies each year, when its inventory runs out, it is not feasible to do another large print run and then manage that inventory for years to come. In the past, low-sales books would have gone out of print. With POD, publishers can keep those books available to readers without having to manage significant inventory.

The complaint our bookstore manager was making seemed mostly about these larger publishers using POD.

General POD quality constraints

Yes, there are differences in quality between traditional offset publishing and print-on-demand publishing. Generally, you have more control and more choices with traditional print than you do with POD.

Limited control

With large print runs (or even just a smallish run at the local print shop), you probably have someone assigned to the job who checks the files, flags any size or color issues, and might even help you adjust the files for proper printing.

However, POD publishing is largely automated. Once you’ve submitted files and they have passed the basic technical checks (nope, no help making sure your colors print correctly), everything is basically automated. Each time a book is ordered, it just goes through the print queue.

More variability

Because POD creates one book at a time, there is more variability in the product. This variation shows up primarily in the trimming of the cover and the interior and in color variation on the cover. The POD platform will replace books that fall out of spec, so call customer support if you receive print books that you believe do not meet spec—but be realistic about what that means.

It is considered “normal” variation for placement to shift as much as 1/16 to 1/8 inch from your design. So think about the interior of your book where you have 1/2-inch margins at top and bottom. Movement up or down could result in the top margin being 3/8 inch and the bottom 5/8, or vice versa. To counteract this issue, I prefer to use more generous margins rather than the minimum allowed. This type of placement shift can also be especially noticeable on the book spine, which typically has little wiggle room.

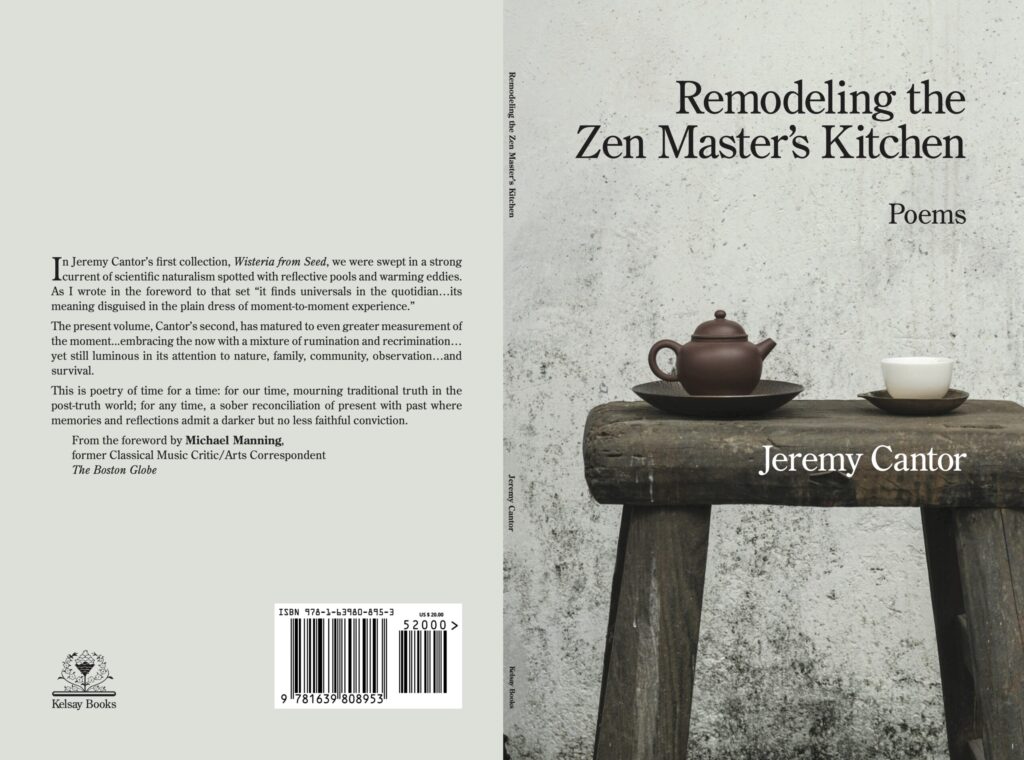

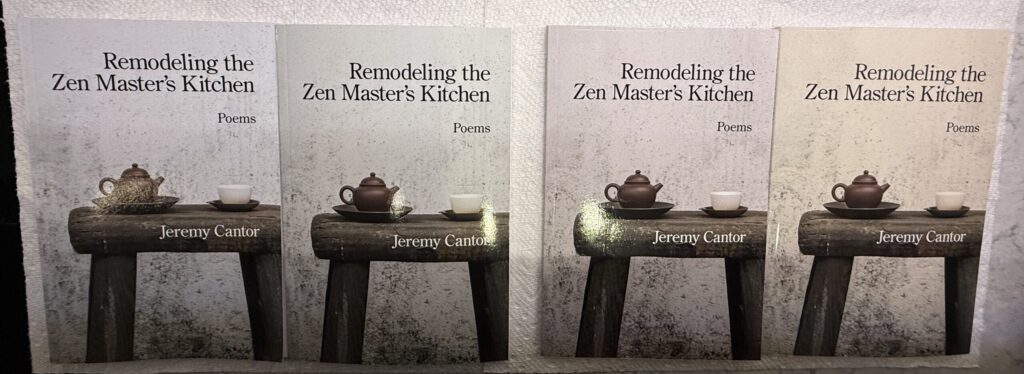

Reader Jeremy Cantor sent pictures that demonstrate color variability on the cover of his book, Remodeling the Zen Master’s Kitchen (Kelsay Books, 2025). (Thanks, Jeremy—super useful!) Here is the original cover as submitted:

And here are four print-on-demand copies of the book from KDP:

To me, the second one looks about right, and maybe the first seems close, but the other two seem (to my eye) to be completely different tones.

When the publisher contacted KDP support, they were informed that all four were within the Delta E (ΔE) tolerance. Delta E is a measure of how far apart two colors are in a given color space (usually CIELAB, a color space that is independent of the device). Here is a rough scale for how Delta E is interpreted:

- 0 to 1 – Imperceptible; the colors look identical to the human eye.

- 1 to 2 – Excellent match; perceptible only to a trained eye.

- 2 to 3 – Slightly visible difference; generally acceptable in print.

- 3 to 5 – Noticeable; may or may not be tolerated, depending on the item.

- 5+ – Obvious difference; usually unacceptable.

I could not find any official documentation for KDP and IngramSpark on Delta E, but based on experience, I would guess they tolerate something in the 3 to 5 range. I would also hazard a guess that some colors are more susceptible to the variation being visible—for instance, perhaps softer, neutral colors show color shifts more than stronger, brighter colors. (This would be a good question for your cover designer in the early stages of design.)

Not being an expert qualified to define Delta E in detail, I tried to find a couple of articles in lay terms for those who want to read more: Here is one article and another article from companies in the print industry (2D and 3D).

Limited options

Because of the automation in POD, certain choices are standardized for efficiency. You get a limited selection of paper—typically white or cream paper with limited weights/thicknesses; there is no special high-end paper with a deckle edge or toothed texture. KDP and IS use standard paper of reasonable weight; I find the IS paper a bit thinner than I would like, allowing a little more show-through of the text on the opposite side of the page, but it’s passable. And IS does have a premium-weight paper available if you want to pay for it.

For covers, you can choose a glossy or matte finish. There is no embossing (raised type), debossing (indented type), or foil stamping (often used with embossing). The matte finish on the cover sometimes makes colors a little muddier than I would like, and I have heard complaints that the gloss finish sometimes peels, but I have not experienced that.

Even with the somewhat limited choices for POD books, my clients find there are plenty of options to create a book they like and are proud of.

Quality by book type

Quality constraints apply to both paperbacks and hardbacks, but the two forms have their own quality characteristics as well.

POD quality on paperbacks

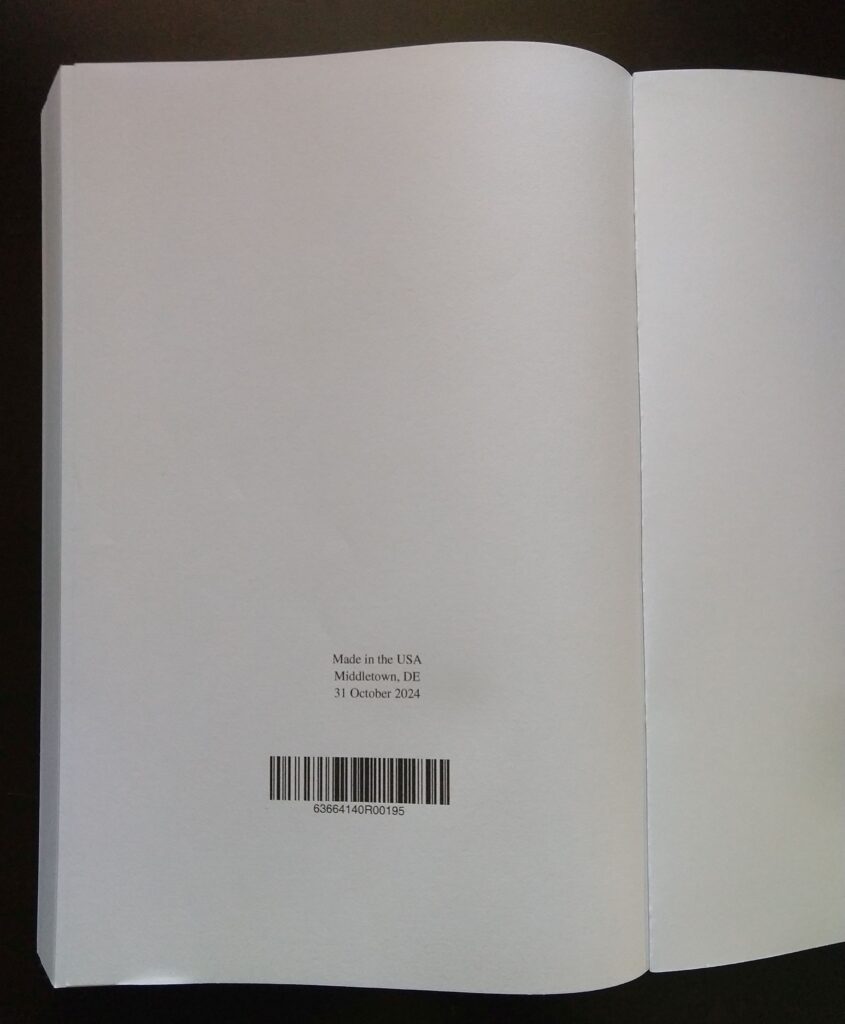

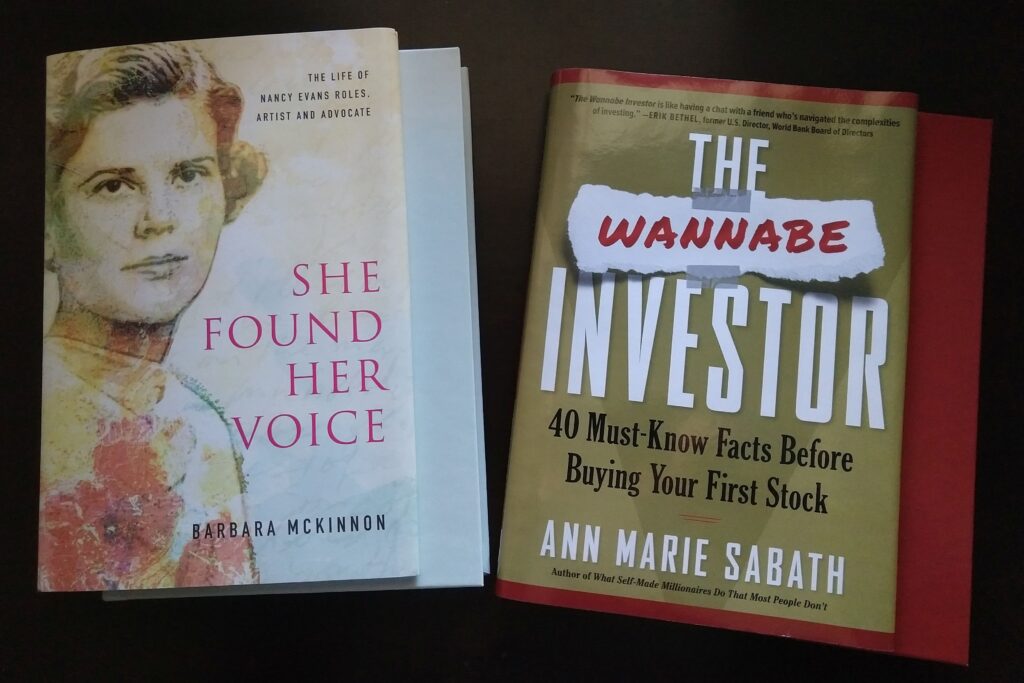

Whether POD or traditional, paperbacks are typically perfect bound. The pages are glued together at the spine and the text block is glued to a cardstock cover. The variance between publishing methods may show up in the quality of the paper or the glue, but for most nonfiction books I work on, those are nonissues. Unless you compare books side by side, standard paperbacks from POD and traditional runs are nearly indistinguishable. The main signifier of a POD paperback is the barcode on the last page of the book (hardbacks have them too).

Are there occasionally production issues with POD paperbacks? Yes—bad glue, so the book falls apart; low toner, so the printed text is not consistent. These are issues to complain about to the POD platform, but in my experience they are uncommon.

Nutshell: POD paperbacks and traditional paperbacks are of comparable quality, and POD is entirely appropriate for most nonfiction books.

POD quality on hardbacks

POD hardbacks are definitely identifiable and are generally not as well constructed as traditionally published hardbacks. However, that does not mean they are poor quality.

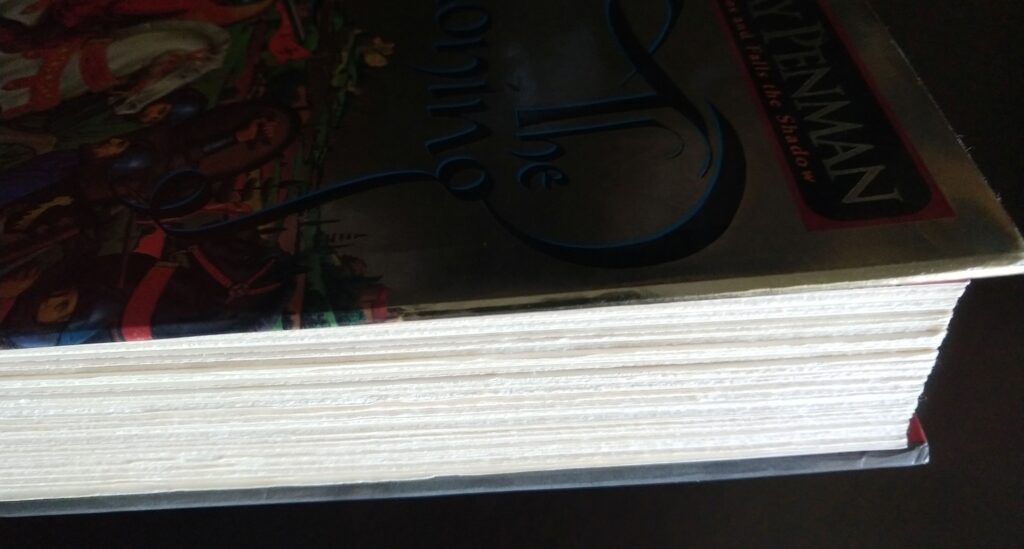

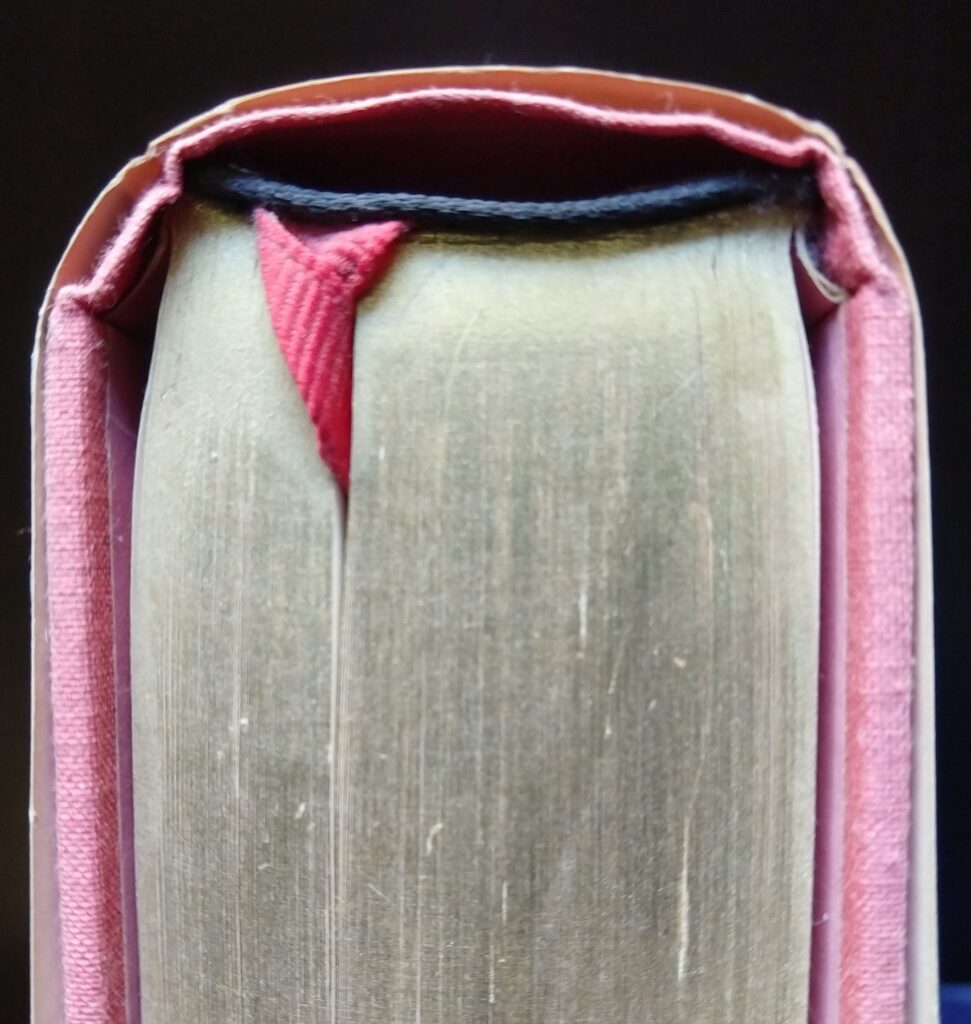

On higher quality traditional hardbacks, rather than having the pages glued as they are in a perfect bound paperback, the interior pages are sewn together in folded groups of pages (called signatures), which allows the pages to lie flat. Sometimes the entire interior is sewn to a spine backing before being attached to the cover. (Not all traditionally published books are sewn though; some are glued.)

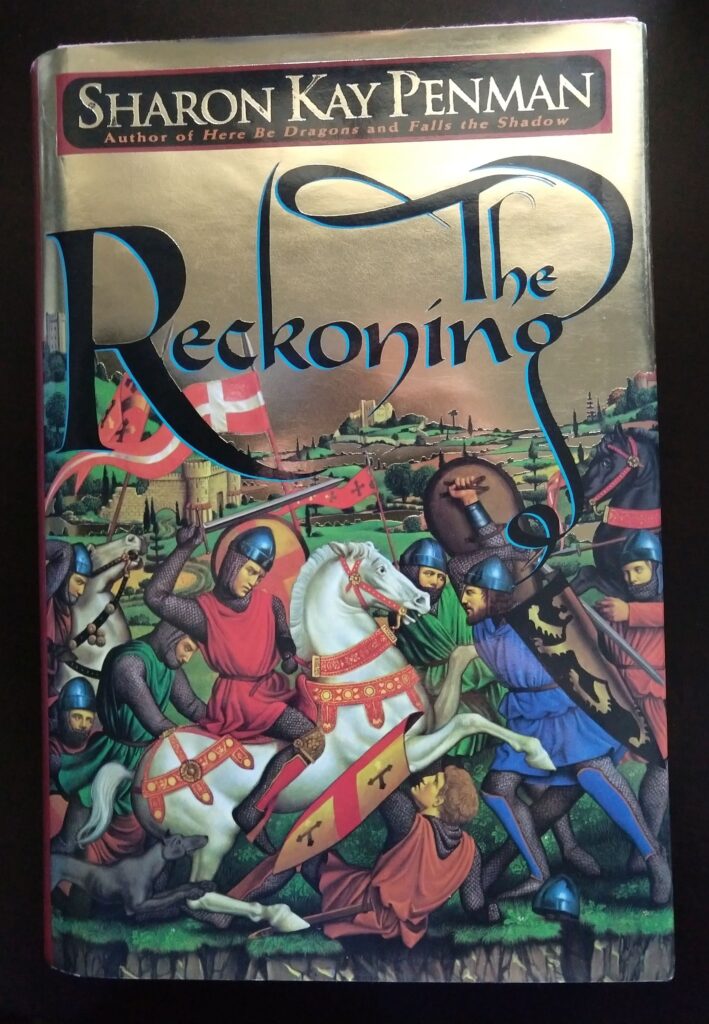

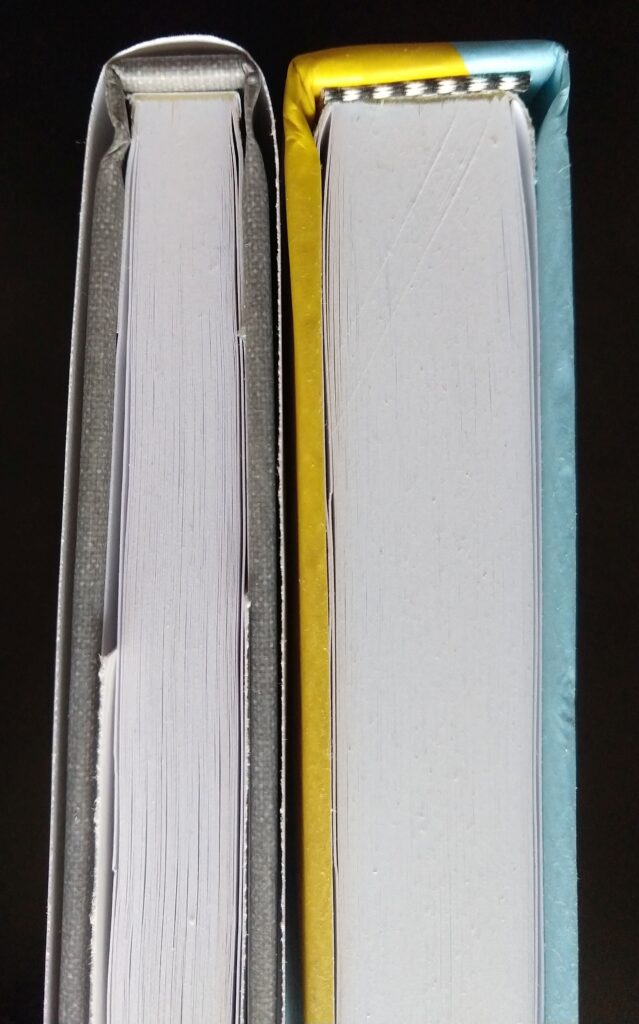

With POD hardbacks, the POD platform essentially creates a paperback of the book, then attaches the paperback cover to the “boards.” This can make POD hardbacks feel flimsier than traditional ones. If you look at the spine, you can see the difference in construction. KDP and IS have one small difference here: KDP adds a little piece of fabric to the spine to mimic the sewn approach and hide the visibility of the pasted interior; IngramSpark does not add this little nicety.

What IngramSpark offers that KDP does not is dust jackets. When you have just the cover on the boards, it is called casebound (think “textbook”). Dust jackets are the removeable paper cover that is folded around the boards. With respect to quality of dust jackets, the paper is fine, but IngramSpark is horribly inconsistent in folding the dust jackets. So even if your cover is designed accurately, you may find yourself refolding jackets that are off-center.

IS also lets you customize the casing to color coordinate with the dust jacket—for instance, a light teal that complements a floral pastel cover or a red that matches a red and gold cover—which adds to the custom feel of a project.

Nutshell: POD hardbacks are definitely not as well constructed as traditionally published hardbacks, but even with their limits, they are still pretty nice.

So what are the big quality problems with POD?

The biggest POD quality issues may actually come from POD users not knowing how to set up the book files correctly.

For instance…

- You must understand how the cover templates are set up, where the “safe space” is for text and images, and how to align objects properly so they are centered on the final product.

- In the interior, if you don’t allow a large enough gutter margin—the margin in the middle of the book—your text can get swallowed.

- If you don’t use high enough resolution for images, photos come out grainy.

- If you don’t use the proper ink coverage, the text may appear grey rather than black, or you may have bleed-through from too much ink.

When you set up your POD book files correctly, many quality issues disappear.

If you have construction quality issues, complain to the POD platform. If the quality does not meet their defined standards, they will provide a refund or a replacement.

Do the quality differences matter?

Let’s not lose sight of the forest for the trees: Do the quality differences between POD and traditional publishing really matter? Mostly, I would say no.

Print-on-demand publishing eliminates gatekeepers. It lets the small players get in the game. It gets books—stories, ideas, information—into the world.

Are there quality issues? Sometimes. But does everything need to be top tier? No. You don’t buy socks and underwear at Neiman Marcus—you get them at Target or Macy’s. You save Neiman Marcus for the sharp suit and shiny shoes. POD is like Macy’s—solid quality but not high end.

I do love a beautiful, high-quality, luxurious-feeling hardback (especially if it has gilt edges and a ribbon bookmark sewn in), but I don’t need that quality on every book I read. Print-on-demand publishing opens the book world to more voices, and as long as the quality is “good,” I can live with the trade-off of its not being “best.”

At Clear Sight Books, we strive for high quality in everything we do, and that includes designing books that work well with print-on-demand technology. Looking for help or advice on your POD project? Get in touch at karin@clearsightbooks.com.